GUAX-PPS

Your globally integrated one-stop-partner : From concept to delivery

GUAX-PPS is your partner in the procurement process of complex mechanical and mechatronic parts, completely tested functional assemblies as well as for injection molds for plastic- and metal parts.

From development and pilot series optimization to serial production and delivery into your warehouse: We take full responsibility of the entire supply chain process for you.

01. GUAX-Optical

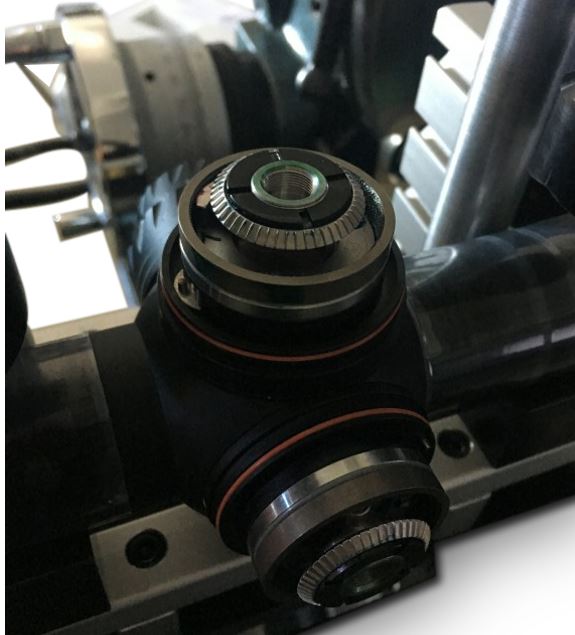

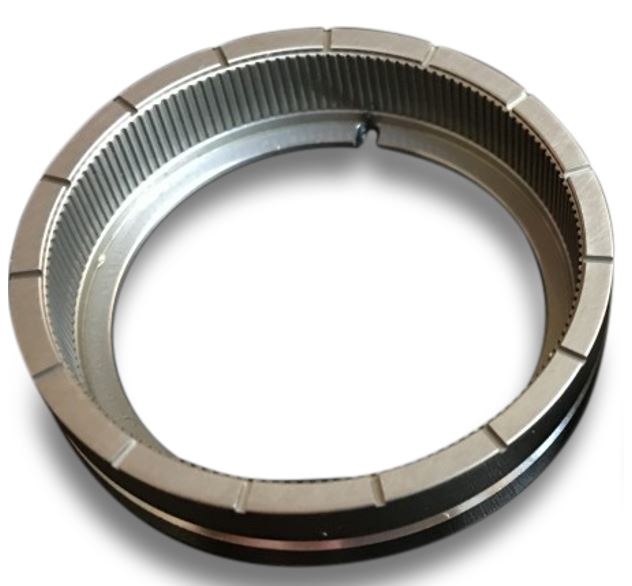

We produce precision parts and assemble them into function-tested assemblies for riflescopes, telescopes and binoculars.

02. GUAX-Automate

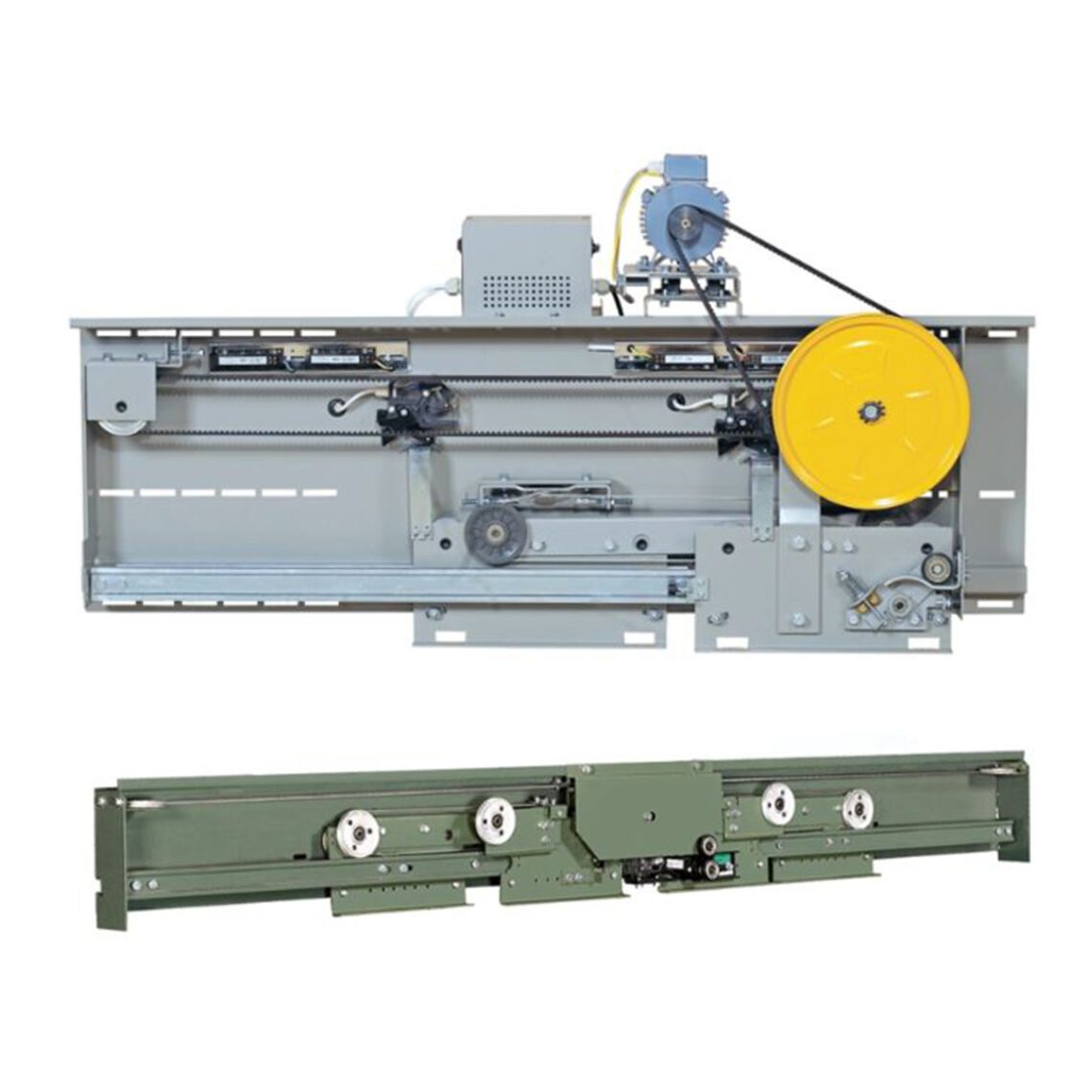

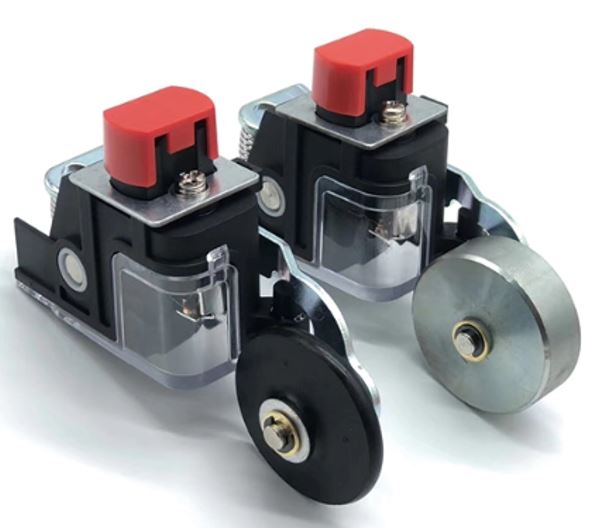

We develop and manufacture precision parts and function-tested assemblies for automatic sliding doors, elevators, escalators and platform doors for subways and commuter trains according to your requirements.

03. GUAX-Tool

From small molds with weights of 1000 kg to large molds with tool weights of 20 t and more, we produce all kinds of molds for you..

04. GUAX-SCM

GUAX-PPS can take care for defined packages from your procurement projects completely end-to-end.

About us

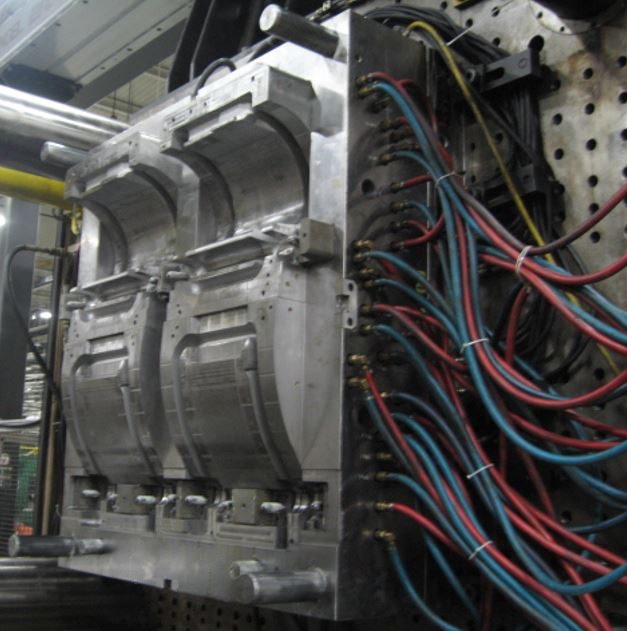

It all began in 1996 with a worldwide search for procurement opportunities for large injection molds for automotive bumpers. It took a lot of patience, because the markets were not yet well developed at that time.

Our managing director Axel Gümpel has been rooted in international production and logistics for over 30 years. His business and technical focus in connection with the consistently established partnerships with process engineers, toolmakers and production specialists are the essential basis for the successful project management of GUAX-PPS.

OUR PORTFOLIO IS CONTINUOUSLY EXPANDING.

Today, we cover the entire procurement chain in various industries. Focal points have emerged in the optical equipment industry as well as in door automation and passenger flow. The construction of injection molds is still our passion.

Please feel free to ask us – we certainly have solutions for your requirements too.

WE KNOW HOW IMPORTANT SMOOTH PROCESSING IS FOR YOU.

We take care of every step end-to-end. From inclusion in the tendering process to after-sales service: We closely follow every process step and always keep comprehensive documentation for you.

LOW TOTAL COST of ownership combined WITH PRECISE QUALITY ARE OUR KEY TO YOUR SUCCESS.

Our unique pricing policy will surprise you.

Thanks to lean and seamless processes in materials- and quality management, production and logistics, we can be convincingly competitive in the market.

Strict adherence to the agreed quality is our top priority.

For us, perfect customer service is a natural part of our mission statement and concept for success.

Axel Gümpel

is at your disposal for any information

Transparent and cooperative communication with our customers is a key success factor for us. We cordially invite you to get to know us.

Please feel free to send us your inquiries – preferably with drawings or sketches and estimated quantities. We will respond quickly and send you indicative quotations. In this way you will be able to estimate our competitiveness realistically and without obligation as a basis for further trustful cooperation.

FEEL FREE TO CONTACT US

By E-Mail, via the CONTACT FORM or by TELEPHONE:

01. GUAX-Optical

We produce precision parts and assemble them into function-tested assemblies for riflescopes, telescopes and binoculars.

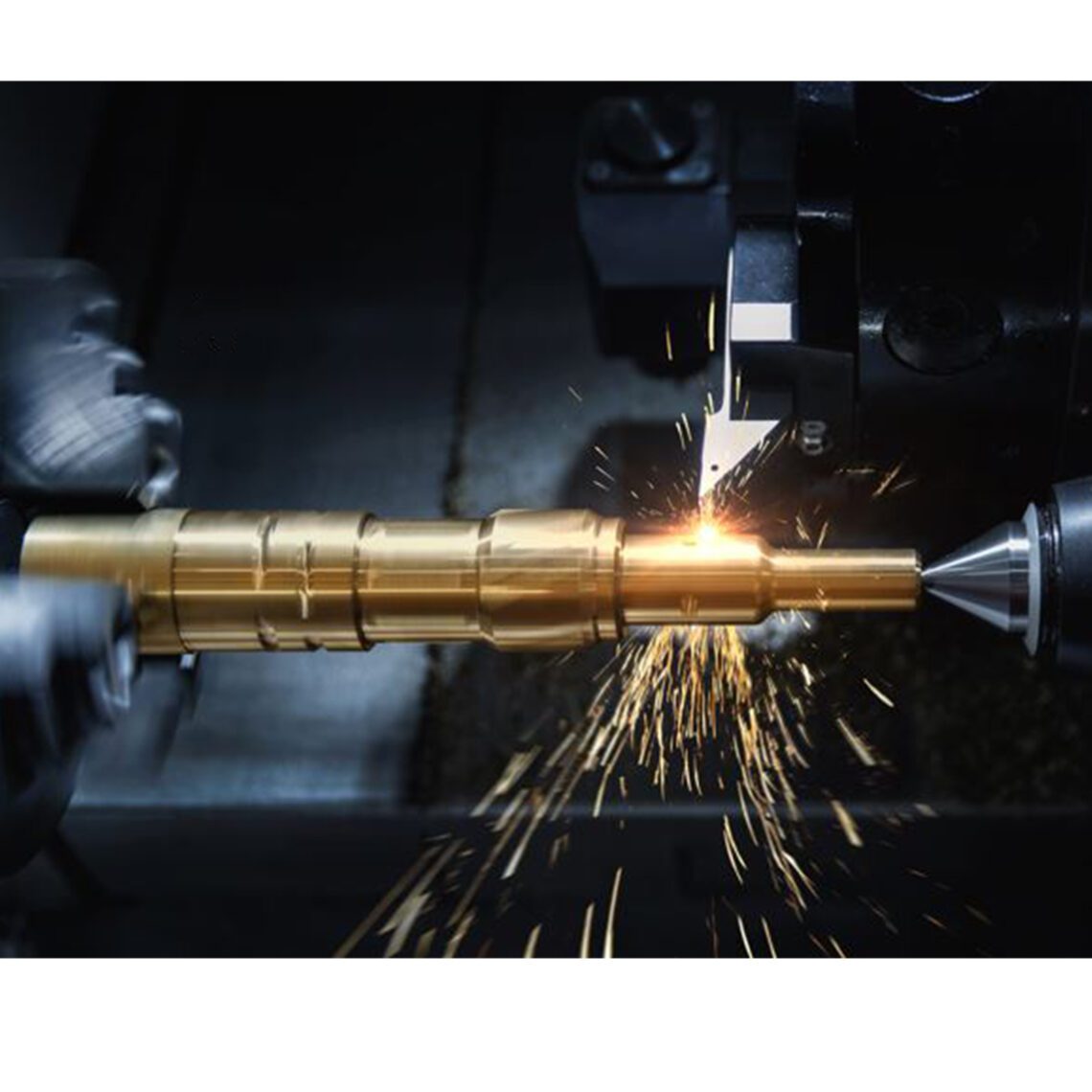

Individual parts in complex geometries from various materials in metal and plastic are manufactured on our state-of-the-art CNC-controlled machining centers.

We develop and produce tools for castings in plastic and metal ourselves in our tool and die shop.

02. GUAX-Automate

We develop and manufacture precision parts and function-tested assemblies for automatic sliding doors, elevators, escalators and personal screen doors for subways and commuter trains according to your requirements.

We supply you with various assemblies such as locking systems, carriages, deflectors as well as with fully assorted assembly sets consisting of standard- and OEM-parts.

We develop and produce tools for castings in plastic and metal ourselves in our tool and die shop.

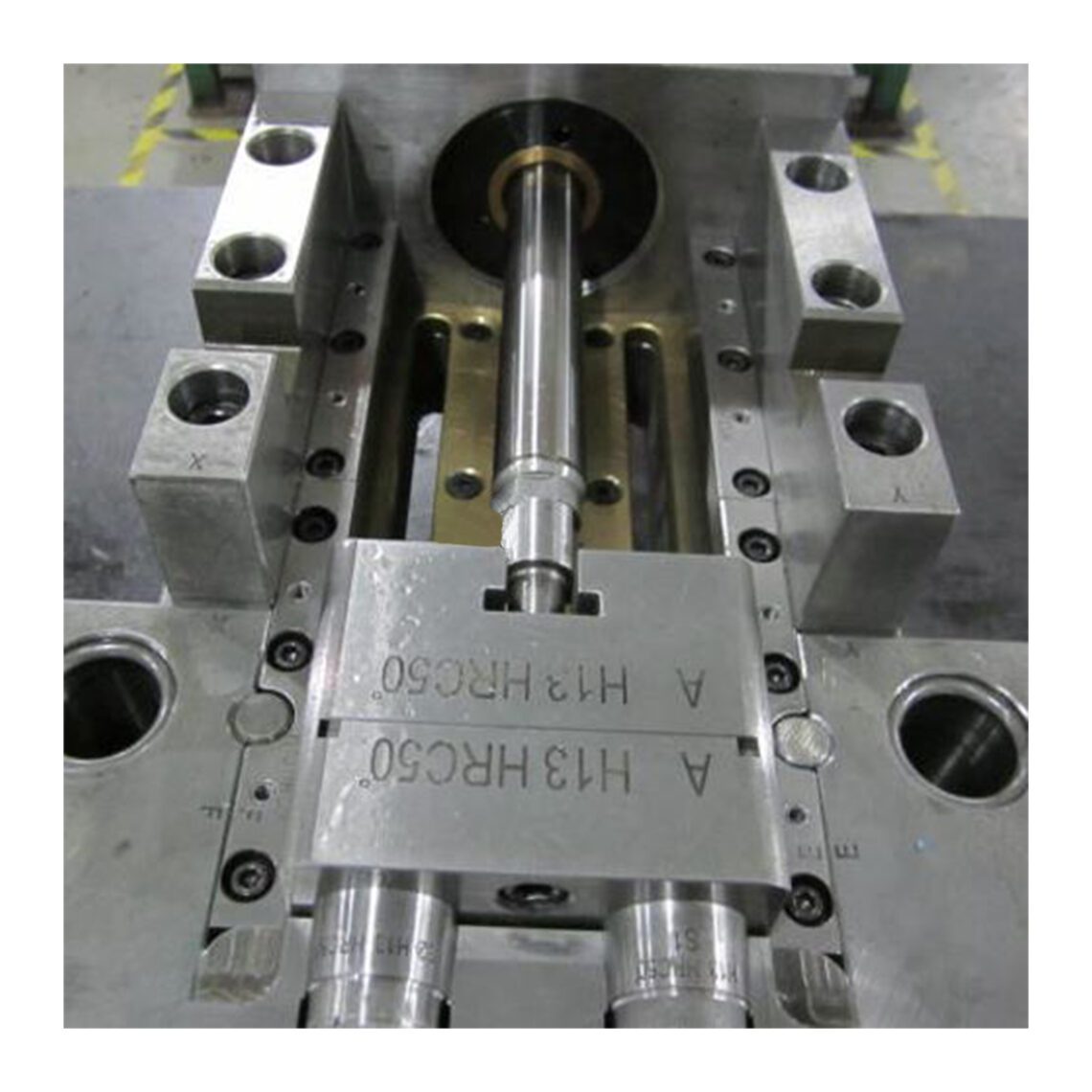

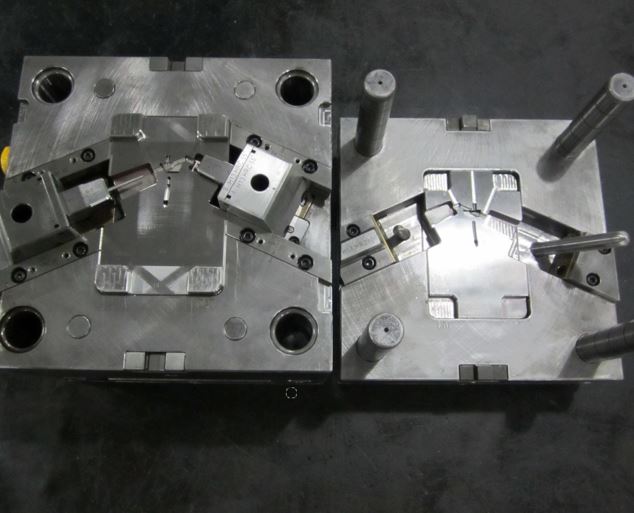

03. GUAX -Tool

We have been designing and manufacturing injection molds for plastic and metal (MIM) for decades. This has enabled us to build up extensive know-how in state-of-the-art mold technologies. From small molds with weights of 1000 kg to large molds with tool weights of 20 t and more, we produce all kinds of molds for you.

We have no restrictions regarding the materials processed, the demolding concepts or the degree of automation.

We design the molds according to your guidelines regarding hot runners and standard parts used. Therefore, we guarantee maintenance and spare parts supply according to your requirements.

You can provide us with your design specifications or let us make suggestions. Finally, we approve the design together and go to the steel. At the latest after 4 weeks we are ready for sampling on our extensive injection molding machine park

04. GUAX- SCM / Sourcing

Every procurement project requires a great deal of interaction between development, product management, the internal and external production units, logistics service providers and many other stakeholders.

GUAX-PPS can take care for defined packages from your procurement projects completely end-to-end. For the in-house manufacturing we concentrate on these processes.

Purchased parts will be efficiently taken care of by our sourcing specialist, focussing on our well established partnerships. Your preferences always have the highest priority.

Thanks to our decades of experience in handling complex procurement projects in various industries, we can also provide you with taylor made project support.

Budget discipline, transparent costs and comprehensive information about the state of affairs are crucial for joint success for all parties. We take care of it.

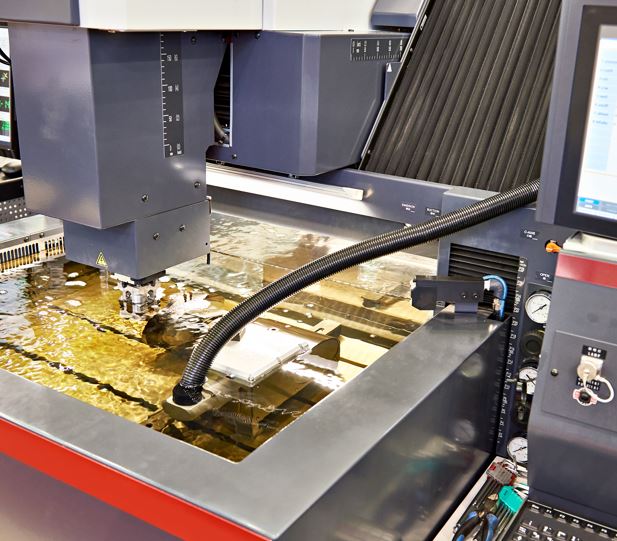

Manufacturing Processes

Benefit from our decades of experience and profound expertise in the following manufacturing technique:

METAL AND PLASTIC PROCESSING

POSTPROCESSING

Tool and Mold making

GAUGES AND ASSEMBLY DEVICES

SURFACE TREATMENT

Contact

We stay at your disposal for any information you may require and look forward to your contact.